Don't Blame the Plates

Why are you always replacing bumper plates in your weight room? Good question...most coaches, athletic directors and facility managers tend to blame the bumper plates manufacturer. There are several things to consider when investigating the reasons for bumper plates damage.

- Bumper Plates Type

- Type of Use

- Frequency of Use

- Floor Surface or Platform Type

Most Bumper Plates are Tough

The truth is, most commercial bumper plates are reasonably tough. Most bumper plates are made with either recycled rubber, or virgin rubber materials. Both types are typically durable and hold up to continued use. We have found that most bumper plates manufacturers usually get the blame for broken and damaged bumper plates, although in most cases it is not the manufacturer's fault.

What is the Cause?

More times than not, the cause can be traced back to the wrong flooring used or inadequate platform construction. Without proper force reduction and minimizing vibration, bumper plates will eventually fail. The constant impact of bumper plates with a hard surface will cause failure ultimately, resulting in broken plates. Most weight room floors that we have inspected use a simple 3/8" or 8mm recycled rubber for their flooring. This is not enough to protect the substrate (concrete), or the equipment from damage of repeated drops from today's lifting standards.

Wrong Flooring For Inlay Platforms

The majority of high schools and many of the colleges that we visit each year have the wrong rubber flooring choices for their inlay platforms. The issue begins when the decision maker; the coach, athletic director or in some cases the superintendent, are simply not informed or educated properly on the material needs of an inlay platform. Rubber flooring providers, companies that sell basic rubber flooring to health clubs and other fitness facilities are not experienced in the actual needs of a weight room using inlay platforms. The typical flooring material used in commercial health clubs and fitness centers is a 3/8" or 8mm recycled rubber. It is much less expensive to buy, ship and install. When it is installed, it looks like any other inlay platform. To the coach or athletic director, it looks like the proper inlay weight lifting platforms seen in other facilities, but in reality it is a problem waiting to happen.

Inlay Platforms Trending Up

Let's face it, college strength training programs are the lead and mentors of our high school strength and conditioning programs. What they do at a college level is what our high schools want to mimic. There's nothing wrong with that, it's the way we develop. For safety, aesthetics, and expanded programming, inlay weightlifting platforms are ideal in most cases. Many schools are replacing their traditional weightlifting platforms with either inlay flooring or a simple alternative solution of a low-profile, all-rubber custom platform that uses a 19mm or 3/4" profile height. The traditional platforms that are being replaced, typically are 3" to 4" in height, with steel frames, wood center boards and hard rubber drop zones.

Inlay Platforms Require Thicker Flooring

The fact is that adding inlay weightlifting platforms require thicker flooring. The reason for thicker flooring comes down to basic physics. The rigidity, density and thickness of material dramatically impact the force reduction value in any floor surface. To achieve both a durable and stable surface with shock absorbing values, you must have a stacked or layered floor surface. This results in performance sports flooring that requires thicker than the traditional 3/8" or 8mm recycled rubber flooring.

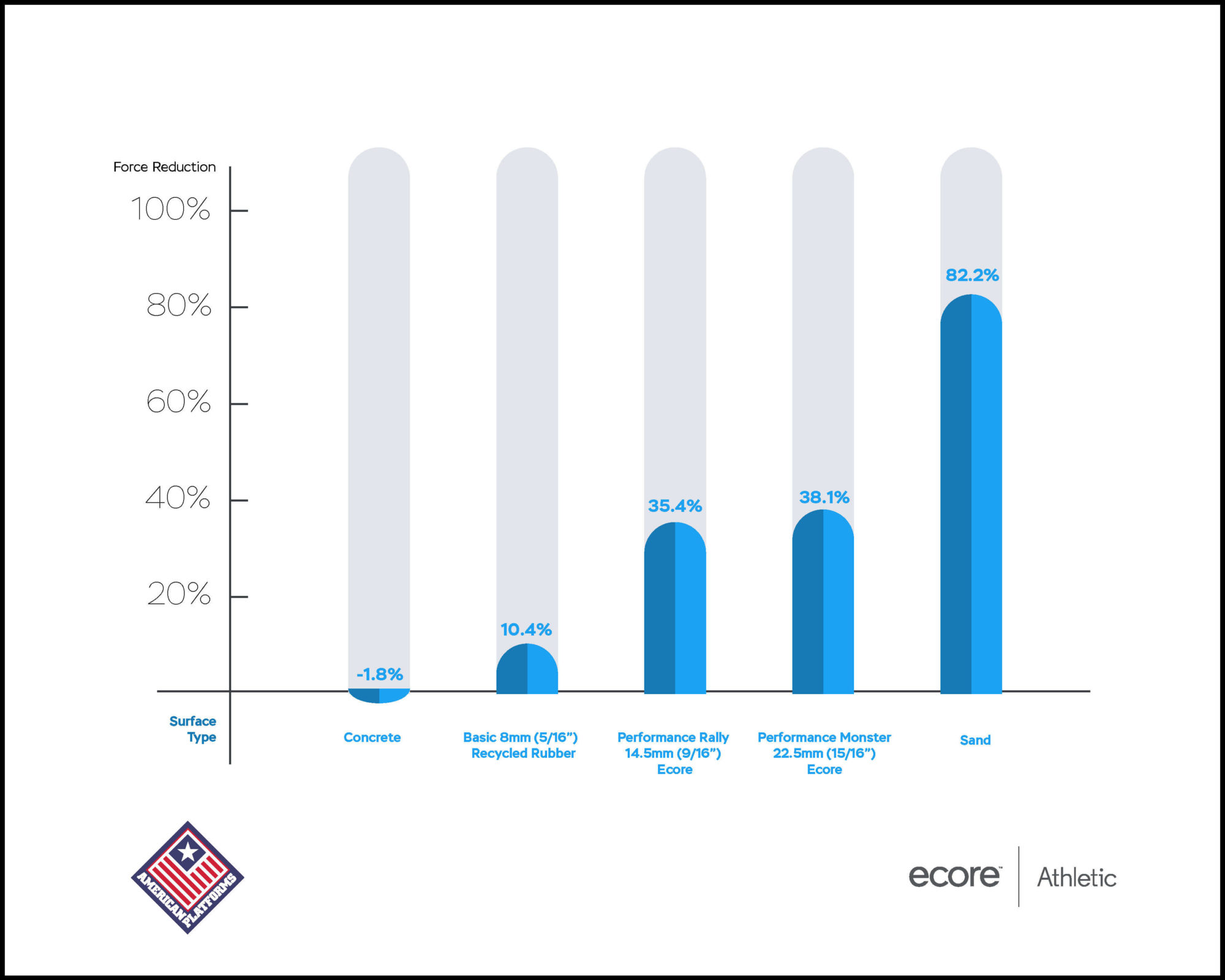

The problem we have seen for several years now, since the trend of inlay platforms has been around, so has the use of inadequate or rubber that is simply too thin and doesn't perform properly. The term used today is Force Reduction. Force Reduction is just what it sounds like, it is a measurement of how much force is reduced when either an athlete or equipment such as bumper plates, makes an impact or contact with the floor or weightlifting platform surface. This may help you better understand why the use of thin, inadequate performance floor surfaces can lead to damaged bumper plates, and worse yet, injured athletes.

Damaged 3/8” Weight Room Flooring

Solutions For Weight Room Flooring

Replace the Floor

The obvious solution is to replace the current flooring with new flooring and inlay platforms with the proper materials. These materials are typically much thicker than what is currently being used in high schools, colleges, and other facilities today. To achieve the ideal force reduction and energy restitution, we recommend using a layered or stacked product, where two very different rubber compounds are used to produce a dynamic performance floor surface. This dynamic performance floor surface consists of both force reduction and energy restitution. By combining a less dense rubber compound with a higher density rubber compound, the outcome produces both a higher level of force reduction and energy restitution.

Force Reduction

Again, force reduction is as it sounds, where the impact and force experienced by both the athlete and equipment coming in contact with the floor surface is reduced. You can review a simple chart we have created using testing results from a 3rd party laboratory. Force reduction is important for the long term health of your athletes and to protect the life of your equipment. In most if not all cases reviewed, force reduction and energy restitution are antagonistic, meaning when one value increases, the other reduces. The science behind Ecore Athletic flooring merges the two needs and produces a product with the best of both worlds. Both force reduction and energy restitution.

Energy Restitution

The importance of providing adequate energy restitution revolves around the athlete. To avoid early fatigue and low performance, a higher energy restitution floor surface is most desirable. If you think of bouncing a basketball on a court and when you have the ball bounce back as it is intended, all is well. When you are bouncing the ball on the court and the ball hits a "dead spot" in the court, the ball doesn't return as it normally does. That spot, has low energy restitution. This may be caused by several things, but it is a good example of good and bad energy restitution.

The Challenge

The challenge is timing and budget when it comes to choosing a new weight room floor and adding in flooring that will support a safe and effective inlay weightlifting platform system. Many schools would like to move away from the traditional 3" or 4" metal frame weightlifting platforms that they purchased with their strength equipment. Coaches, athletic directors and facility managers see clearly the reasons for having either inlay weightlifting platforms or low-profile rubber platforms. The investment needed for converting an existing weight room floor to an inlay weightlifting platform type can be large. This size of investment requires planning and budget considerations that a school needs the full support of the school district and community in many cases.

The Solution

Many times schools are planning a new or renovated weight room far in advance, yet they need to solve the safety issues and damage to equipment in the meantime. The solution to this immediate need is a custom made all-rubber weightlifting platform that reduces sound and vibration SVR by more than 50%. High quality custom weightlifting platforms can be produced in any size needed with a custom insert to fit your weightlifting rack or rig. These all-rubber custom weightlifting platforms come with a durable, long lasting graphic to display your team or organization's logo or mascot proudly.

Force Reduction Examples Chart